|

|

Symons cone crusher is a improved machine of spring cone crusher. It¡¯s applied in above medium hardness all kinds of ore and rock. Compared with spring cone crusher, it has reliable structure, high efficiency, easy adjustment, low cost and many other advanrages. It¡¯s applied in metallurgy, construction, white fuel, traffic, chemical engineering, construction material to process above medium hardness all kinds of ore and rock, it¡¯s the best choice for large scale stone plant and ore crushing.

This machine is divided into standard type and short-headed type. Generally speaking, the standard type has big feeding granularity and relatively coarse discharging granularity, and the short-headed type has steep crushing cone and small feeding granularity which is conducive to producing fine particle materials, for this reason, the standard type compound cone crusher is generally used for coarse and medium crushing and the short-headed type compound cone crusher is generally used for medium and fine crushing.

Features:

1.Unique Cavity Design

Lamination crushing has a great performance on high hardness material, even and good final product shape, high capacity.

2.Dry Oil Seal

Unique dry oil seal can protect machine from dust, reliable seal, Replacement cycle and service life of parts are lengthened.

3.Overload Protection

Spring system is overload protection to protect machine from metel damage.

4.Rolling Mortar Wall

More material is allowed to be taken into machine, and discharge volume is increased.

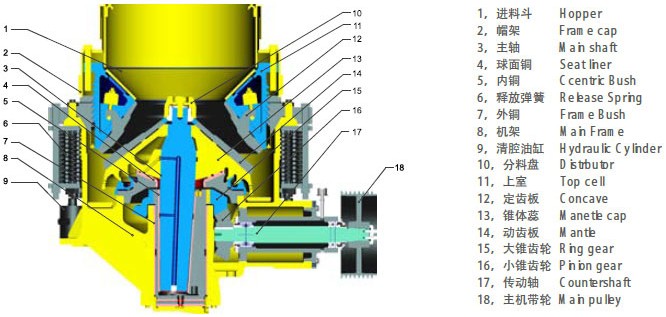

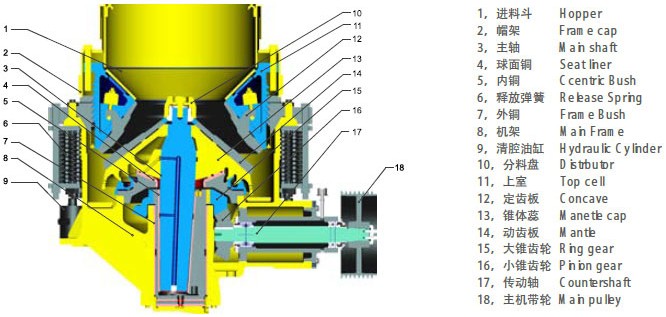

Working principle

When cone crusher begins to work, the electro motor drives the eccentric sleeve through the spring coupling, drive shaft and a pair of angle gear, so that the crushing wall of cone crusher gets close to and then gets away from the surface of the rolling mortar wall fixed on the adjusting sleeve, and the ores inside the crushing chamber will be constantly impacted, squeezed and bent to be crushed.

Specification:

|

Moving cone diameter(mm) |

Type and spec |

To ore size(mm) |

Row ore mouth adjusting range(mm) |

Capacity

(t/h) |

Power

(kw) |

Equipment weight(t) |

|

Silent edge |

Mouth edge |

|

914 |

standard |

PYS-B0910 |

83 |

102 |

9-22 |

40-100 |

75 |

14.6 |

|

PYS-B0917 |

159 |

175 |

13-38 |

55-180 |

|

PYS-B0918 |

163 |

178 |

25-38 |

105-180 |

|

Short head type |

PYS-D0904 |

13 |

41 |

3-13 |

24-100 |

|

PYS-D0906 |

33 |

61 |

3-16 |

24-110 |

|

PYS-D0907 |

51 |

76 |

6-19 |

54-140 |

|

1295 |

standard |

PYS-B1313 |

109 |

137 |

13-31 |

100-200 |

160 |

25.6 |

|

PYS-B1321 |

188 |

210 |

16-38 |

118-280 |

|

PYS-B1324 |

216 |

241 |

19-51 |

155-350 |

|

PYS-D1325 |

238 |

259 |

25-51 |

212-390 |

|

Short head type |

PYS-D1306 |

29 |

64 |

3-16 |

32-180 |

|

PYS-D1308 |

54 |

89 |

6-16 |

74-180 |

|

PYS-D1310 |

70 |

105 |

10-25 |

100-240 |

|

PYS-D1313 |

98 |

133 |

16-25 |

190-260 |

|

1676 |

standard |

PYS-B1620 |

188 |

209 |

16-38 |

181-330 |

250 |

45 |

|

PYS-B1624 |

213 |

241 |

22-51 |

232-450 |

|

PYS-B1626 |

241 |

269 |

25-64 |

270-640 |

|

PYS-B1636 |

331 |

368 |

38-64 |

400-700 |

|

Short head type |

PYS-D1607 |

35 |

70 |

5-13 |

82-230 |

|

PYS-D1608 |

54 |

89 |

6-19 |

120-310 |

|

PYS-D1613 |

98 |

133 |

10-25 |

170-370 |

|

PYS-D1614 |

117 |

133 |

13-25 |

228-370 |

|

2134 |

standard |

PYS-B2127 |

253 |

278 |

19-38 |

344-798 |

355 |

89 |

|

PYS-B2133 |

303 |

334 |

25-51 |

550-1100 |

|

PYS-B2136 |

334 |

369 |

31-61 |

800-1270 |

|

PYS-B2146 |

425 |

460 |

38-64 |

880-1400 |

|

Short head type |

PYS-D2110 |

51 |

105 |

5-16 |

172-450 |

|

PYS-D2113 |

95 |

133 |

10-19 |

318-540 |

|

PYS-D2117 |

127 |

178 |

13-25 |

410-628 |

|

PYS-D2120 |

152 |

203 |

16-25 |

530-688 |

|

|