|

|

The roll crusher is widely used for crushing high hard and medium hard materials in such industrial departments such as metallurgy, building material and refractory. It has the features of low noise, little powder dust, reliable performance and convenient maintenance.

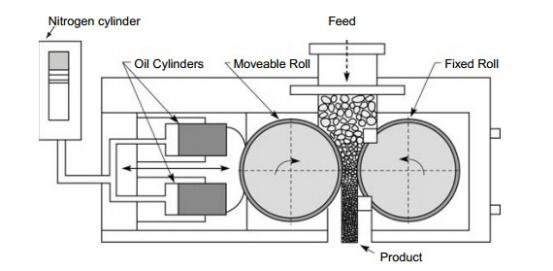

The Inner Structure of Roll Crusher:

The main structure of the wheel gearing is composed of fixed roll, movable roll, drive shaft, machine box, chassis, cover piece and long gear cover. The motive power of the machine comes from the V-belt pulley of the electromotor, and a pair of middle reduction gear will make the fixed roll rotate, and then a pair of long gear drive on the other side of the fixed roll will drive the movable roll, and the two rolls perform relative movement to squeeze the materials.

Feature

1. advanced hydraulic control system, users can adjust the pressure according to the material hardness

2. With sensor, the roller crushers can load relief when overload

3.The advanced hard faced technology improves the roller covers' life.

4. Good performance, low cost in operation and easily maintenance.

Working principle

The adjustment of discharging granularity: There is a wedge-shaped or gasket adjustment device between the two rolls, and on the top of the wedge-shaped device, there is an adjusting bolt. When the adjusting bolt pulls up the wedge, the wedge will lift the movable roll from the fixed roll, so that the gap between the two rolls will become large, and the discharging granularity will become large. When the wedge goes down, under effect of the pressure spring, the gap between the two rolls will become small, and the discharging granularity will become small. The gasket device adjusts the discharging granularity through increasing and decreasing the number or thickness of the gasket, and when the number of the gasket increases, the gap between the two rolls will become large and the discharging granularity will become large; when the number of the gasket decreases, the gap between the two rolls will become large and the discharging granularity will become small.

Specification

|

Type |

Rolls Diameter (mm) |

Max Feeding Granularity (mm) |

Row Partial (mm) |

Processing Power (t/h) |

Roller Speed (r/min) |

Power (kw) |

Weight (t) |

|

2PGC0405 |

450*500 |

200 |

0-50 |

20-55 |

64 |

2*5.5 |

3.4 |

|

2PGC0607 |

600*750 |

300 |

0-50 |

60-125 |

64 |

2*11 |

7.23 |

|

2PGC0909 |

900*900 |

300 |

0-50 |

125-180 |

65.5 |

2*30 |

13.8 |

|

2PGC0912 |

900*1200 |

300 |

0-50 |

130-200 |

65.54 |

2*45 |

18 |

|

2PGCY1212 |

1260*1220 |

500 |

0-100 |

150-250 |

110 |

2*75 |

30 |

|

2PGCY1215 |

1260*1500 |

500 |

0-100 |

180-300 |

110 |

2*90 |

36.6 |

|

2PGCY1414 |

1400*1400 |

600 |

0-100 |

200-400 |

125 |

2*110 |

44 |

|

2PG0402 |

400*250 |

25 |

1-8 |

5-10 |

200 |

2*5.5 |

1.3 |

|

2PG0604 |

610*400 |

40 |

2-20 |

13-35 |

120 |

2*15 |

3.7 |

|

2PG0705 |

750*500 |

50 |

2-25 |

50 |

50 |

2*18.5 |

6.95 |

|

2PG1008 |

1000*800 |

60 |

3-25 |

35-70 |

100 |

2*45 |

22 |

|

2PGY1208 |

1200*800 |

60 |

3-30 |

70-120 |

110 |

2*75 |

27 |

|

2PGY1510 |

1500*1000 |

70 |

3-30 |

120-200 |

110 |

2*132 |

36.2 |

|

|